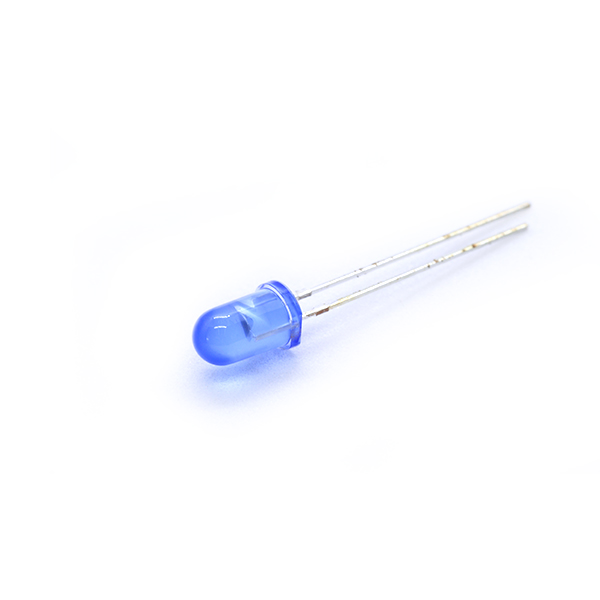

The following requirements must be strictly followed during the welding process of direct insertion infrared LED beads:

1、 In actual production, it is necessary to wear anti-static gloves, anti-static wrists, etc. The soldering iron should be grounded, and it is strictly prohibited to touch the two pins of the infrared LED bulb with hands. Due to the working temperature of 60% -90% on the workbench, static electricity from the human body can damage the crystalline layer of infrared LED beads. After working for a period of time, the infrared LED beads will become ineffective and dead, and in severe cases, they will immediately die.

2、 The welding temperature is 260 ° C and the welding time is 3 seconds. Excessive temperature and prolonged time can burn out the chip. In order to better protect the infrared LED beads, the adhesive of the infrared LED beads and the PC board should be kept at a distance of 2 mm or more to facilitate the dissipation of soldering heat in the pins.

3、 The normal operating current for a direct insertion infrared LED bulb is 20mA, and even small fluctuations in voltage can cause significant fluctuations in current. Therefore, in circuit design, different current limiting resistors should be paired according to the voltage drop of the infrared LED beads to ensure that the infrared LED beads are in the best working state. If the current is too high, it will shorten the service life of the infrared LED beads, and if the current is too low, it will not meet the required brightness requirements. When Shenzhen Chengguangxing Optoelectronics supplies in bulk, they will perform spectral and color separation on the infrared LED beads, which means that the parameters of the infrared LED beads in the same package of products are consistent, ensuring product consistency.

Address: 5th Floor, Building 12, Changfeng Industrial Park, Dongkeng, Fenghuang Street, Guangming District, Shenzhen, Guangdong Province

Tel: 13632942401

Email: led_best@163.com

Copyright © 2023 Tianshi All Rights Reserved 粤ICP备2021179733号